In today’s fast-paced manufacturing landscape, precision and efficiency aren’t just nice to have—they’re essential for staying competitive. Whether you’re producing synthetic textiles, industrial fabrics, or composite materials, traditional manual cutting processes often fall short. That’s where a programmable hot knife cutting machine enters the scene.

What Is a Programmable Hot Knife Cutting Machine?

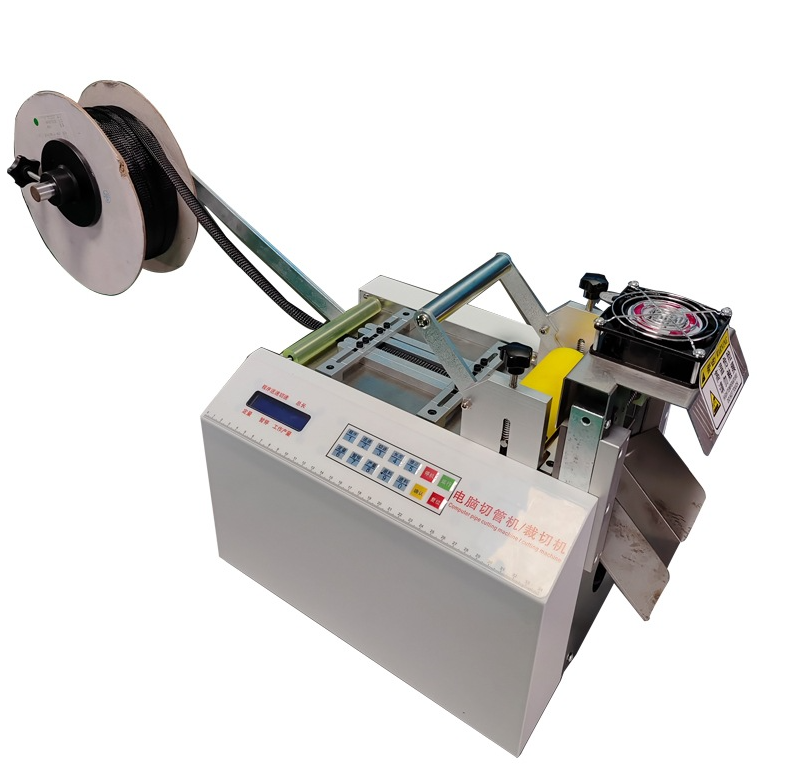

A programmable hot knife cutting machine is an automated cutting system designed to heat and slice through synthetic materials with precision. The “hot knife” melts through the fabric or material, sealing the edges as it cuts. This prevents fraying, ensures clean lines, and minimizes post-processing.

What sets programmable systems apart is their ability to be customized for repeatable, high-volume production with minimal operator involvement. Once set up, these machines follow exact cutting parameters consistently—something that’s difficult to achieve with manual labor.

Top Benefits: Why More Manufacturers Are Making the Switch

If you’re still relying on manual or semi-automated systems, you may be missing out on several key advantages:

Improved Accuracy and Repeatability

With programmable settings, each cut follows the exact dimensions specified. This consistency is especially valuable in industries where precision determines quality or performance.

Faster Production Speeds

Time is money. A programmable hot knife cutting machine can significantly reduce production time by automating repetitive tasks and running continuous cutting operations.

Edge Sealing to Prevent Fraying

When cutting synthetic materials like nylon, polyester, or webbing, frayed edges can compromise product integrity. Hot knives seal the edges as they cut, eliminating this issue.

Reduced Waste and Lower Material Costs

Precision cutting means fewer errors. This translates to less material waste, which directly impacts your bottom line.

Labor Efficiency

A programmable system reduces dependency on skilled labor for cutting tasks, freeing up your workforce for other critical operations.

Common Applications Across Industries

Programmable hot knife cutting machines are used in a variety of sectors:

Automotive and Aerospace: For cutting insulation, composites, and webbing with exact specifications.

Apparel and Textile: In production of straps, belts, and labels where clean edges are crucial.

Packaging and Logistics: For creating custom straps, harnesses, or securing systems.

Outdoor and Military Gear: Where durability and resistance to fraying are essential.

No matter the industry, these machines offer flexibility to cut complex shapes, long lengths, or batch products in one streamlined workflow.

Is the Investment Worth It?

Upgrading to a programmable hot knife cutting machine may seem like a significant investment, but when you factor in improved output, quality, and long-term operational savings, the return on investment becomes clear. Especially for medium to high-volume production environments, the cost savings in labor and materials alone often justify the upgrade within a short period.

Final Thoughts

As manufacturing processes continue to move toward greater automation and precision, the tools you use must evolve too. A programmable hot knife cutting machine can help you boost efficiency, enhance product quality, and future-proof your production line. If you’re looking to gain a competitive edge through smarter, faster, and cleaner cutting, now is the time to consider the upgrade.

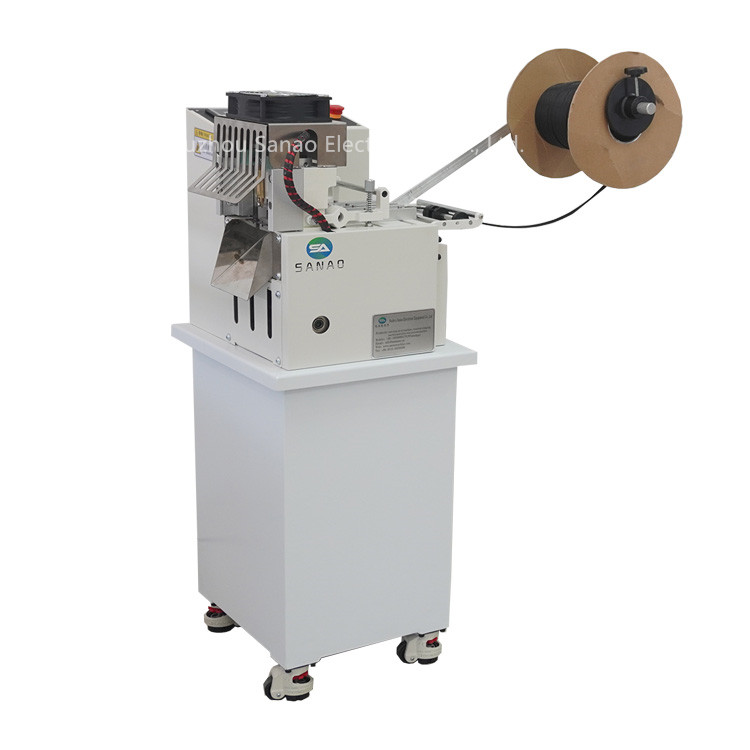

Ready to optimize your cutting workflow? Contact Sanao today for tailored hot knife cutting solutions that meet your specific production needs.

Post time: Jun-03-2025